Medium-pressure (MP) UV lamp

A medium-pressure (MP) UV lamp has some important differences compared to the more well known low-pressure (LP) UV lamps. These differences are major reasons to select UV systems with medium-pressure lamps:

- high power

- energy efficiency

- compact size

- reduce quantity needed in a UV reactor

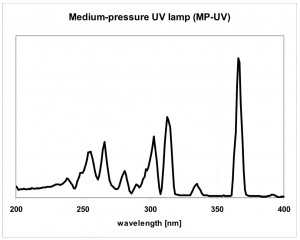

- broad range of wavelengths (200 – 400nm)

- photobiological effects

Some applications may require the use of medium-pressure UV lamps because they emit a broader range of wavelengths. Such applications include:

- dechloramination in public swimming pools (reduction of all chloramines, mono-, di- and trichloramines, only reached by the emission of wavelengths between 200 and 400nm.

Two other important reasons to use medium-pressure UV lamp technology is:

- to reduce the footprint of the installation, as high-powered medium-pressure lamps greatly reduce the size of a UV reactor.

- to reduce the quantity of UV lamps because medium-pressure UV lamps have higher power fewer are required compared to a low-pressure UV lamp systems.

Low-pressure (LP) UV lamp

Low-pressure (LP) UV lamps have some important differences compared to medium-pressure (MP) UV lamps:

- low power

- efficiency

- larger size

- greater quantity needed in a UV reactor

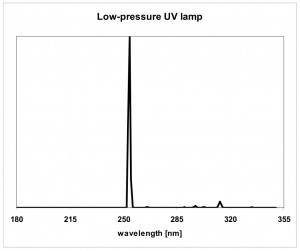

- limited range of wavelengths (254nm) emitted

Some applications use of low-pressure UV lamps, mainly because of:

- low capacity (single UV lamp)

- frequent STOP and GO operations

Two other important reasons to use low-pressure UV lamp technology are:

- high efficiency of the lamp, up to 40% of the power converts to germicidal energy,

- specific 254 nm wavelengths, well known for disinfection purposes.